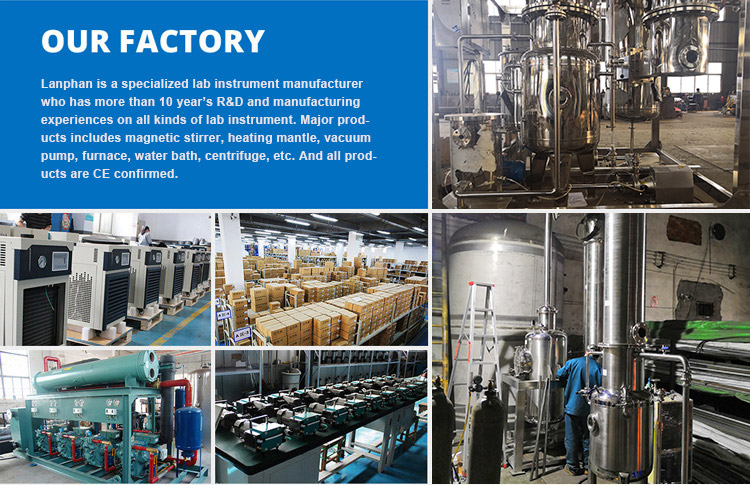

Henan Lanphan Industrial Co., Ltd. integrates industry and trade.

The company has advanced production equipment, excellent workforce,

stable domestic and foreign partners.

The company has a number of outstanding employees with a bachelor's

degree or above and a TEM-8 English major. The company's

after-sales personnel have overseas master's degrees. Professional

technical personnel provide strong backing for the company.

Henan Lanphan Industrial Co., Ltd. currently mainly sells two

categories of products:

Scientific research instruments: rotary evaporator, glass reactor,

vacuum pump, drying oven, magnetic stirrer, heating jacket,

short-path distillation, centrifuge, falling film evaporator,

molecular distillation equipment, etc.;

Piping equipment: rubber joints, metal joints, air duct joints,

etc.;

Henan Lanphan Industrial Co., Ltd. occupies a leading position in

the industry with high-quality products and reasonable prices.

Products are exported to more than 100 countries and regions, with

customers all over the world, and have won the trust of domestic

and foreign customers with a good reputation.

The company adheres to the concept of "people-oriented", respects

customers, employees, partners, suppliers and social groups; takes

integrity as the purpose of the company's development, "honesty" is

the foundation, and "trust" is used; the pursuit of excellence and

continuous innovation.