Falling Film Evaporator Lab Stainless Steel Distillation CBD

Product Description

Falling film evaporators are widely used in the evaporation and

concentration of water or organic solvent solutions in medicine,

food, chemical, light industry and other industries, and waste

liquid treatment. This equipment is especially suitable for

heat-sensitive materials and continuous operation under vacuum and

low temperature conditions. It has high evaporation capacity,

energy saving and consumption reduction, low operating cost, and

can ensure the invariance of materials during the evaporation

process.

Feature

The equipment operates continuously under vacuum and low

temperature conditions, with large evaporation capacity, energy

saving and consumption reduction, low operating cost, and can

maintain the original composition of the processed materials to

he greatest extent.

It is widely used in food, medicine, food deep processing,

beverage, light industry, environmental protection, chemical

industry and other fields. The evaporator can be designed into

different technological processes according to different material

characteristics, and can also be equipped with an automatic control

system according to the requirements of different users.

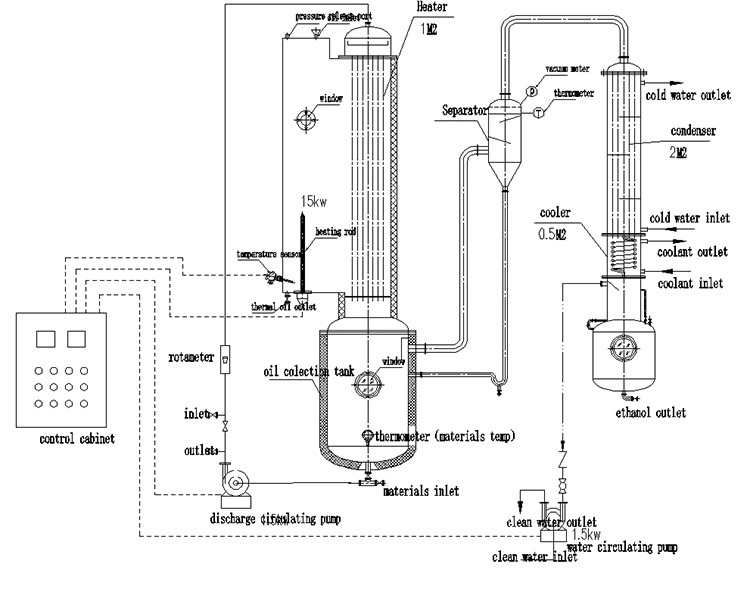

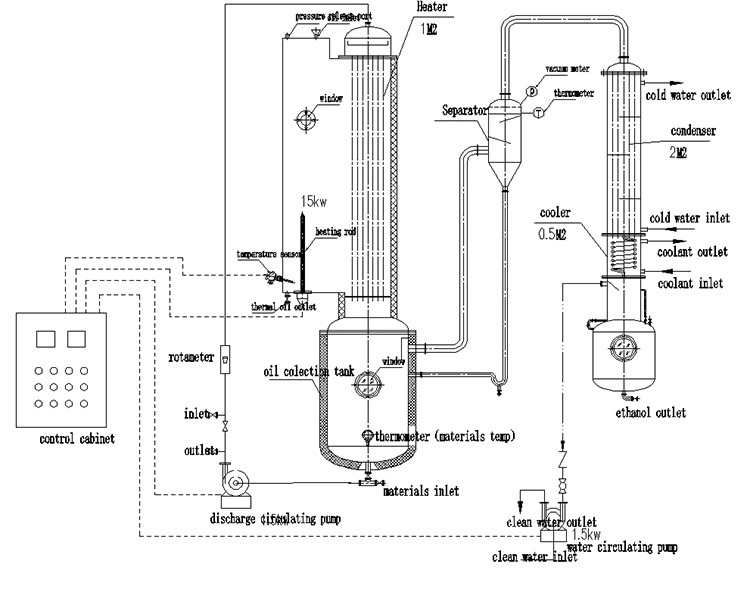

Operation process

1. Exhaust the gas in the equipment to create a vacuum environment;

after the vacuum is sufficient, add water to change the material.

2. Start the vacuum pump. If it is a water ring vacuum pump, it

should be started without load.

3. When the pump is running and before starting, take care not to

interrupt the cooling water of the pump mechanical seal to avoid

damage to the pump mechanical seal.

4. When there is a sudden power failure, the valve should be closed

immediately; the materials in the equipment and its pipelines

should be discharged as soon as possible; the heated water should

be diluted until it does not crystallize or solidify.

5. During operation, if the vacuum is low or after restarting,

check whether there is air leakage at the flange and joints

immediately.

Working Theory

This equipment belongs to liquid film concentration equipment,

which has high heat transfer rate and short heating time. It

applies to chemical, liquid medicine, juice, and dairy production.

The theory is that the feed liquid is added in the middle of the

evaporation chamber. Under the action of vacuum and gravity, the

accelerating pressure head of the liquid is smaller than that of

the rising film type, and the boiling point is also smaller. The

temperature difference between the electric heating and the feed

liquid is large, so the heat transfer effect is better.The steam

enters the evaporative separation chamber for separation. The

secondary steam is discharged from the top of the chamber and the

concentrate is extracted from the bottom.

Maintenance

1. Always check whether the oil cup of the pump is short of oil,

and whether the cooling water in the mechanical seal is broken.

2. Always check the flanges and joints of the equipment for air

leakage.

3. When the mechanical seal of the pump is damaged, it should be

replaced in time.

4. When the check valve rubber ball and rubber gasket are damaged,

they should be replaced in time.

5. If the indications such as thermometer, vacuum gauge, pressure

gauge, etc. are inaccurate, they should be proofread or replaced in

time.

6. The surface of the equipment should not be rubbed with a hard

scrubbing tool (such as steel brush) to avoid scratches and

scratches on the stainless steel surface.

| Name | Electric heating single effect falling-film evaporator |

| Model | LXQX - 5-00 |

| Evaporation capacity | 5kg/h |

| Total power | 18kw |

| Cooling water consumption | 1T/h (inlet 25℃, outlet 35℃) |

| Boundary dimension | 1350x600x1800mm |

| Equipment configuration list | heater, evaporator, feed pump, vacuum pump, condenser, equipment

support, material pipeline, etc. |

Corollary Equipment

Application

Workshop